Note that the control limits for the Xbar chart are based on the average range (Rbar).

Xbar r charts series#

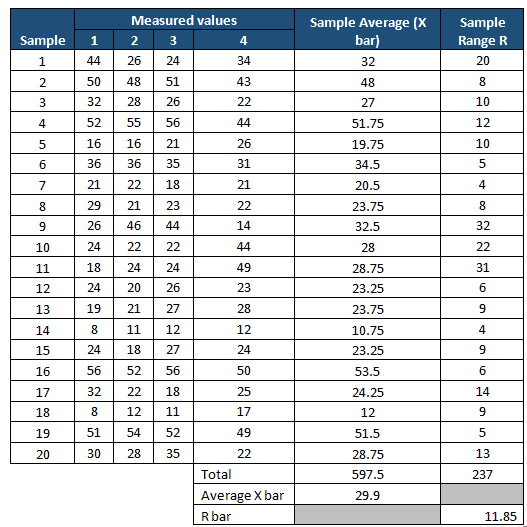

Please see our two-part newsletter series on Xbar-R control charts if you would like more information on Xbar-R control charts. The control limits for the R chart are given below.ĭ4 and D3 are control chart constants that depend on subgroup size. The X with the two lines above ("X double bar") is the overall average Rbar is the average range and A2 is control chart constant that depends on subgroup size. The control limits for the Xbar chart are given below. After you have enough points, you calculate the overall averages and the control limits. You plot the average on the Xbar chart - which monitors the variation between subgroup averages. You also calculate the subgroup average - the average of the five You plot those range values on the R chart - which monitors the variation within a subgroup.

It is a measure of the variation in the individual results. The range is the maximum value - minimum value. You take those five measurement results and calculate a range. At the start of each hour, you collect five samples from the production line and measure a quality characteristic, X. The Xbar chart examines the variation between subgroups Suppose you are making a product.The range chart examines the variation within a subgroup.Xbar-R Control Chart Example: Small Average Range Ĭlassical Xbar-R Control Charts The classical Xbar-R control chart is designed to look at two types of variation:.

Xbar r charts how to#

We will then look at how to handle these types of situations by using three control charts. You will see that the control limits on the Xbar chart are very tight and most of the points on that chart are beyond the control limits. We then take a look at what the Xbar-R control charts often looks like when you have situation where there is a significant difference between the within-subgroup variation the between-subgroup variation. We start with a brief review of Xbar-R charts. But what happens when the process is such that is not possible for the short-term variation to be consistent with the long-term variation? This month's newsletter takes a look at how to address situations with control charts where the within-subgroup variation is significantly different from the between-subgroup variation. The long-term variation is given by the between subgroup variation on the Xbar chart. If you are using an Xbar-R chart, the short-term variation is given by the within-subgroup variation on the range chart. But it also means that the short-term variation is consistent with long-term variation. What does it mean when a control chart indicates that a process is in statistical control? It means it is consistent and predictable - you can predict what the process will do in the near future. Once mastered, it provides data to leaders on changes they should make as well as measuring the success of changes put into place.Xbar-mR-R (Between/Within) Control Chart January 2011 Control charts are really a study in variation. Note: D3, D4, and A2 were all obtained from the Control Chart Constants Table for a sample size of n = 3.Īn x-bar R chart is one of many tools in Lean and Six Sigma that accurately measure an organization’s performance. The subgroup sample size used in the following example is three. The following is an example of how control limits are computed for an x-bar and R chart.

They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. They measure performance on any type of process, from all the steps in a manufacturing process to determining the time customers must wait in line at a pharmacy.Īn x-bar R chart can find the process mean (x-bar) and process range (R) over time. X-Bar R charts are commonly used to examine the stability of a process over time.

0 kommentar(er)

0 kommentar(er)